Submitted by Christine Georgiou on Tue, 07/04/2020 - 11:38

“We are privileged to have so much in Cambridge – and we should be using it to help others.”

So says Dr Laura James, our Entrepreneur in Residence here, a role that usually sees her exploring ways for third sector organisations to work with this Department, and connecting projects related to sustainability and climate.

But recently, following the coronavirus outbreak, she’s been volunteering with community groups on the rapid design and local production of personal protective equipment (PPE), and supporting work on open source hardware and software to enable greater access to critical equipment.

People around the world are trying to understand the problems, trial and scale solutions, work globally on questions of design and process, and locally on identifying specific needs, coordinating logistics and manufacture. And she says Cambridge could, and should, be helping.

“I am acutely aware of Cambridge's exceptional privilege in tech capability (both making, and software and clinical engineering), seed funding and crowdfunding capabilities, and policy access too. We should be using these assets to benefit other regions that are not so fortunate, not just helping ourselves” she argues.

“This means opening, sharing, documenting etc, from the earliest stage and working with others and thinking of those in greatest need. We should be considering how our efforts, paid or otherwise, might assist those outside our local bubble, who will already be supported so much better than those in other parts of the UK, let alone the billions living in low and middle income countries.” And she has many suggestions for how we can do that.

The big manufacturing consortia will be the best way to deliver the complex and critical technology of ventilators. The Institute for Manufacturing (IfM) in Cambridge has a great list of resources around this challenge and other ways manufacturers can help.

The University-led project OVSI is a new initiative to create open source ventilators for low and middle income countries. Dr James is them helping figure out how best to increase access to ventilators through open source, whilst considering liability and safety issues. (This builds on the recent CRASSH research network, Open Intellectual Property Models of Emerging Technologies and Implications for the Equitable Society.)

In the maker and manufacturer communities, there’s great enthusiasm to help with the supply of vital personal protective equipment (PPE) to those working in healthcare, social care and high risk environments. All over social media, we can see people designing, making and experimenting with cloth masks, filters and face shields, etc. But this is complex to do when ‘the NHS’ in fact comprises over 8,000 organisations. To help, Laura is aggregating information on cloth face masks and face shields and has been bridging between various communities working on these items both locally and nationally / internationally, to help them share information and in some cases join forces.

She is bringing together a new group (under the auspices of www.helpfulengineering.org/) to try to smooth the paths of both those needing PPE and trying to make it. “But this is a social problem at least as much as it is a technical and information one,” she says. “The social sector in the UK is under incredible strain right now. Digital and technical support can only help in a modest way, and must meet local needs in collaboration with the community.”

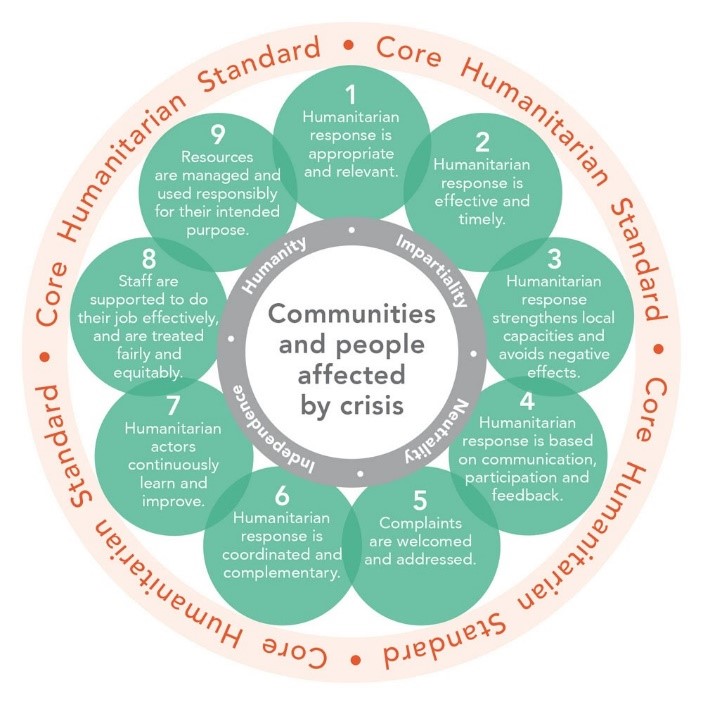

A coordinated response to the problems is vital, she points out. “Technical experts applying their skills in new areas are not always aware of the subtleties of the problem space,” she says. “Crisis response demands that local affected communities are engaged and the needs of the most vulnerable considered and prioritised; this doesn’t always happen when experts parachute in from elsewhere. The Core Humanitarian Standard diagram shows best practice for how we should be responding.”

A coordinated response to the problems is vital, she points out. “Technical experts applying their skills in new areas are not always aware of the subtleties of the problem space,” she says. “Crisis response demands that local affected communities are engaged and the needs of the most vulnerable considered and prioritised; this doesn’t always happen when experts parachute in from elsewhere. The Core Humanitarian Standard diagram shows best practice for how we should be responding.”

In a recent paper, she argues that local manufacturing and new supply chains that work with different organisations and different ways of working should play a role too. “It's not just designs, but access to materials, equipment, skills, testing and distribution which are needed.”